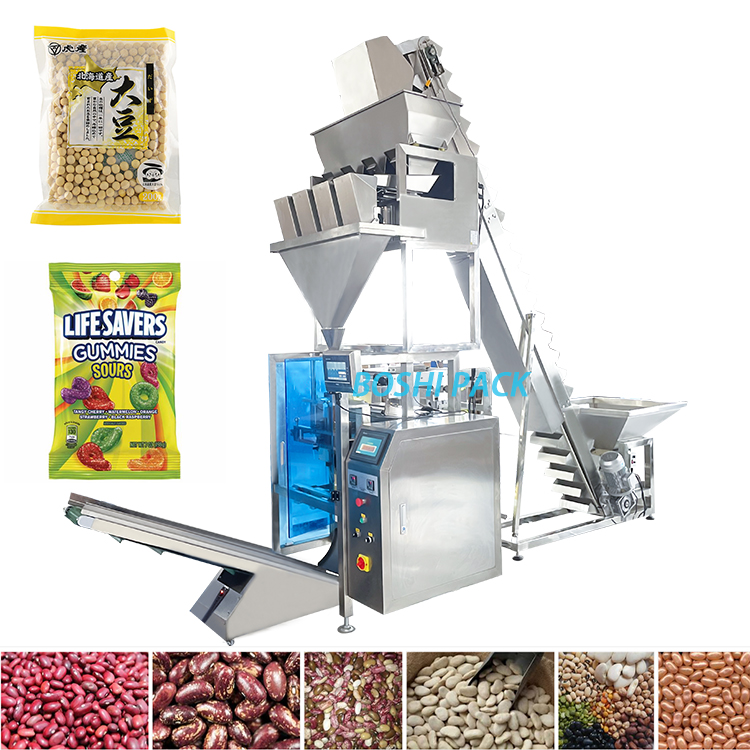

automatic peanut packaging machine nuts packing machine

1.This machine has an imported PLC automatic program control, easy operation.

2.Famous brands configurations, high work efficiency, works stable.

3.Safety protection and alarm function that effectively prevents incorrect packaging.

4.Adjustment of bag deviation just needed to be controlled by the touch screen.

Automatic Peanut Packaging Machine Nuts Packing Machine

►Whole machine main including 4 parts:

1. Z type bucket elevator

2. Computer combination scale

3. Platform

4. Packing machine host

5. Finished products conveyor( If needed)

►Kindly Reminder

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Please tell us the following information while you send us an inquiry. Base on your message, we will suggest the optimum solution to you for reference. Thank you.

1. Your product

2. Bag dimension

3. Bag weight

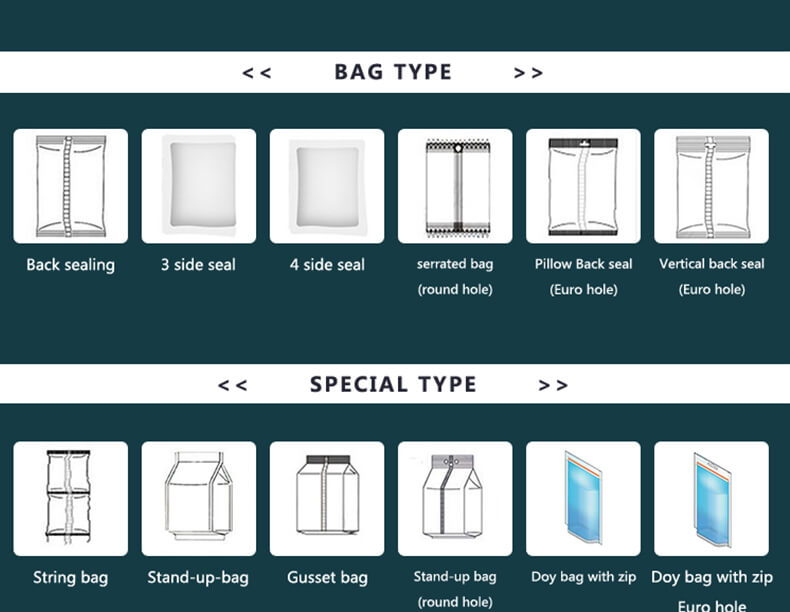

4. Bag shape

►Main Features:

1. Simple structure in linear type, easy in installation and maintain.

2. Adopting advanced world famous brand components in pneumatic parts, electric parts and operation parts.

3. High pressure double crank to control the die opening and closing.

4. Running in a high automation and intelligent, no pollution.

5. Apply a linker to connect with the air conveyor, which can directly inline with filling machine.

►Applications:

Suitable for Meatball, macaroni, hamburgers, popcorn, dry pasta, oats, puffed food, french fries, biscuit, rice crust, jelly, candy, pistachio nut, apple flake, dumpling, rice dumpling, chocolate, frozen food, chicken leg,hardware and medicine such particle, platy, strip and irregular shape.

►Standard Features:

1. The machine use high precision servo film transport system, PLC Program Control, developed touchable Human-machine Interface of Advanced Automatic Positioning, Photoelectric Tracking, Digital Temperature Control,etc.

2. Operation is more simple, perfect. It is the first choice of food packaging industry to Improve the production efficiency,reduce Labor Intensity, improve the grade of packaging equipment.

3. Bag end + middle back sealing temperature control independently, suitable for pure PE, CPP/OPP, BOPP/CPP, PE/polyethylene, PE/aluminum plating, pet/PE, PP, and other heat-sealing packaging materials.

4. It completes the whole procedure of filling, measuring, bagging, date printing, charging(exhausting), product out-putting automatically.

5. High precision, high efficiency without crash the materials.

6. Packaging style diversified, back sealing, gusset bag, string bags, punching, etc.

7. Work environment quiet, low noise, saving energy.

8. A complete set of equipment is economical.

About Us:

FOSHAN BOSHI PACKING MACHINERY CO., LTD.

Extruder and packing machine(For play dough, clay, flour dough, light dough, gel, energy bar ,etc.soft materials)

Cling film packing machine (For vegetable,fruit,meat, fish);

Shrink packing machine (For bottles, toys, books, plate, CDS, foods , commodities, and any other solid products)

Located in Foshan city, next to Guangzhou city, is a professional manufacturer of series packing machine with morn than 13 years experience. Main produce packing machine as follows:

Pillow packing machine (For food, commodities, hardware , toys, soft, loose, solid products packing);

Granule packing machine (Multi-head weigher packing machine - For dry food, such as nuts, chips, candy .-For frozen food, such as dumpling, chicken leg, fish, pork. -For hardware screws. For vegetables,small fruits ,etc)

Line weigher /Volumetric cup packing machine( For small granules like sugar, salt, rice,beans,nuts, grain )

Powder packing machine( For coffee powder, milk powder, instant powder,flour, and etc.);

Liquid packing machine( For sauce, jam, honey, juice, paste, jelly, oil, shampoo, and etc.);

<You may like>

Boshi pack CE automatic beans weighing packing machine for granular products

View Details

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Multi-weigher | |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|