Working principle of liquid filling machine

Working principle of liquid filling machine

2024--11--7

15 years liquid filling machine manufacturer: liquid filling machine It is an essential piece of equipment in the packaging industry, designed to simplify the process of filling liquids into various containers. These machines are highly efficient and ensure accuracy and consistency in filling. In this article, we will take a deep look at How liquid filling machines work, explore their components, operating processes, and the benefits they bring to the manufacturing industry.

Parts of liquid filling machines

Understanding the various components of a liquid filling machine is essential to understanding how these machines operate. Here are the main components:

1.Filling valve: A key component that controls the precise flow of liquid into the container. It ensures precise control of capacity, prevents overfilling or underfilling, and maintains consistency for each unit.

2.Conveying system: An automated system that moves empty containers to the filling position and then conveys filled containers for capping and packaging. It improves production efficiency and minimizes manual operations.

3.Control panel: The central interface for machine operation. It allows the operator to set parameters such as filling speed, container size, and temperature control, ensuring smooth and precise operation. It also monitors performance to meet maintenance needs.

4.Liquid storage tank: A large tank used to store liquids before they are dispensed into containers. The tank is equipped with temperature and viscosity controls to maintain the consistency of the liquid and prevent clogging.

5.Capping device: After the liquid is filled into the container, the capping device automatically covers and secures the lid to ensure hygiene, prevent leakage, and maintain the freshness of the product during storage and transportation.

Here are six benefits of using a liquid filling Machine:

1.Improved Efficiency: Liquid filling machines can significantly speed up the production process by automatically filling jars or bottles. This can increase output and reduce production time compared to manual filling methods.

2.Consistent and Precise Filling: The machine ensures consistent and accurate filling of jars or containers, reducing the possibility of overfilling or underfilling, which leads to waste and dissatisfaction.

3.Reduced Labor Costs: By automating the filling process, fewer workers are required to perform manual tasks. This helps reduce labor costs and improves overall cost-effectiveness for manufacturers.

4.Improved Hygiene and Safety: Liquid filling machines are designed with hygiene in mind, minimizing human contact with the product. This reduces the risk of contamination and ensures that the liquid filling process is clean and safe, meeting health and safety standards.

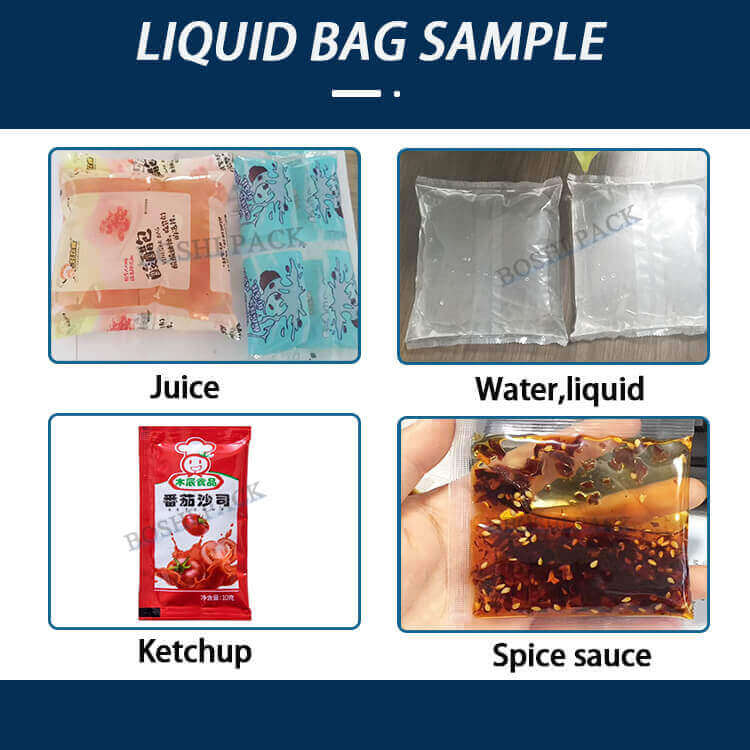

5.Versatility: These machines can handle different types of liquids, including jams, beverages, laundry detergents, juices, sauces, and other similar products. This versatility makes them ideal for companies that produce a variety of food products.

6.Better Product Quality: The precise filling mechanism helps maintain the quality of the jam, ensuring that it retains its flavor, texture, and appearance. This helps provide consumers with a better overall product experience.

These benefits highlight the advantages of using a liquid filling machine in a production environment, making the process more efficient, cost-effective and consistent.

Other Features:

Liquid capsule filling machines are used to accurately fill liquid or paste materials into capsules to ensure dosage consistency and sealing. They are widely used in the pharmaceutical and health care products industries.

The liquid filling machine discharge nozzle is the part where the liquid flows out, which is responsible for accurately delivering the liquid to the container. It is usually designed to be drip-proof, corrosion-resistant, and the flow rate and capacity can be adjusted according to the product type.

A desktop liquid filling machine is a small manual or semi-automatic device that is mainly used to accurately fill liquid products into bottles, jars or other containers. It is suitable for small batch production and is widely used in food, cosmetics, medicine and other industries. The equipment has a compact structure and is easy to operate, suitable for use in laboratories, workshops or small production lines.

Electronic liquid filling machine is a device that uses an electronic control system to accurately fill liquids. It uses electronic metering and sensor technology to ensure the accuracy of the liquid filling amount. It is widely used in food, cosmetics, medicine and other industries and is suitable for small batch production.

In Conclusion

Using a liquid filling machine offers many advantages, including increased efficiency, precise and consistent filling, cost savings through reduced labor, improved hygiene and safety, flexibility in handling different products, and improved product quality. These advantages make it a valuable investment for manufacturers seeking to optimize their production processes and deliver high-quality products to consumers.

Why Choose Boshi for Your Liquid Filling Machines?

At Boshi, we specialize in providing high-quality liquid filling machines that mliquid packaging industry. Here’s why we’reliquid filling equipment needs:

1.Expertise in Liquid Filling Solutions: With years of experience in designing and manufacturing liquid filling machines, Boshi has become a trusted partner for businesses in the food, beverage, and chemical industries. Our machines are engineered to handle a wide variety of liquid products, from juices and oils to cleaning chemicals and more.

2.Customizable and Versatile Equipment: Whether you're packaging viscous liquids, thin liquids, or **carbcarbonated beverages, Boshi offers custom liquid filling solutions that can be tailored to your production line’s specifautomatic liquid filling systems are designed for high accuracy, speed, and efficiency.

3.Advanced Technology for Precision Filling: Boshi's liquid filling machines are built with advanced technology to ensure precision ahigh-speed filling capabilities, easy integration with existing production lines, and the ability to minimize downtime.

4.Comprehensive Customer Support: Our commitment to quality extends beyond equipment. We offer full **techntechnical support and maintenance services to ensure your liquid filling machines continue to operate at peak performance. From initial installation to routine maintenance, Boshi is with you every step of the way.

5.Proven Success in the U.S. Market: Boshi has successfully providedliquid filling equipment to many leading U.S. companies. Our machines are trusted by businesses across a wide range of industries to enhance productivity, reduce costs, and improve product quality.