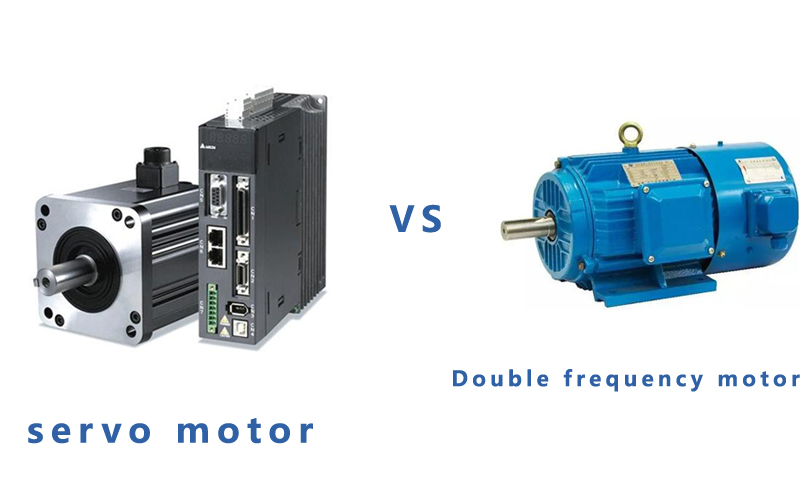

The difference of servo motor & frequency pillow packing machine

| Difference | Double frequency conversion Packing machine |

Servo motor Packing machine |

Remark |

| power | Two ordinary motors, one drives the horizontal sealing and feeding, the other drives the vertical sealing | Horizontal sealing, vertical sealing and feeding are all controlled by independent motors | The three axes can be divided into one servo motor, two ordinary motors; or two servo motors, one ordinary motor; or three servo motors. |

| Mechanical structure | Adjust the cam structure of the knife speed, feed adjustment differential mechanism, feed and cutter power distribution mechanism and other structures。 | Directly driven by motor power | The three-axis structure is simple, reducing mechanical structure transmission and reducing noise. Easy maintenance, less friction and long life. |

| Speed adjustment of horizontal sealing cutter | The cam structure is used to manually adjust the speed of the cutter and move the film synchronously. | No adjustment required, and a motion controller used to automatically track and synchronize. | |

| Material position adjustment | Manual adjustment with differential mechanism | Enter the digital adjustment on the touch screen, or press "Feeding and Paper Linkage" and other materials to the appropriate position, then press "Set as Feeding Offset". | Save material adjustment time. |

| Anti-cutting function | When the material is cut, the whole machine stops working. Need manual readjustment | When the material is cut, the work of the cutter is suspended, and the feeding and longitudinal sealing continue to work. When there is no cutting situation, the packaging machine automatically works normally. | Reduce downtime and increase production efficiency. |

| When the anti-cutting function not installed | When cutting hard objects, damage the cutter. | When cutting hard objects, the servo alarms and the whole machine stops working to fully protect the cutter. | |

| Anti-aircraft bag function | Non | When there is an empty package in the feeding, the vertical sealing and horizontal sealing will be suspended, and the work will continue when there is material. | Reduce the waste of packaging film. |

| Replacement material packaging length | To replace products with large differences in material length, mechanical parts need to be changed and the operation complicated. | When changing the length of the material, the operation is simple, just input the relative parameters on the touch screen. | |

| Recipe function | Non | The parameter settings of the array packaging products can be saved, and the normal production can be achieved by switching directly without re-adjusting the machinery. | Save the adjustment time of replacing packaged products. |

| Requirements for operators | A longer transition period of mechanical familiarization is required, and certain technical requirements are required. | Intelligent and humanized parameter settings, can be used skillfully in a short time. |