Boshi pack high speed automatic card packing machine supplier

The advantage of three servo motor face mask packing machine

1)Three servo motor version, high speed output, stable operation, saving time and film.

2)Interface features easy and quick setting and operation.

3)Self failure diagnosis, clear failure display.

4)High sensitivity photoelectric eye color tracing, numerical input of cutting sealing position for extra accuracy.

5)Temperature independent PID control, more suitable for packaging different materials.

6)Positioned stop function, without sticking knife or wasting film.

7)Simple driving system, reliable working, convenient maintenance.

8)All control is realized through software, easy for function adjusting and technical upgraded.

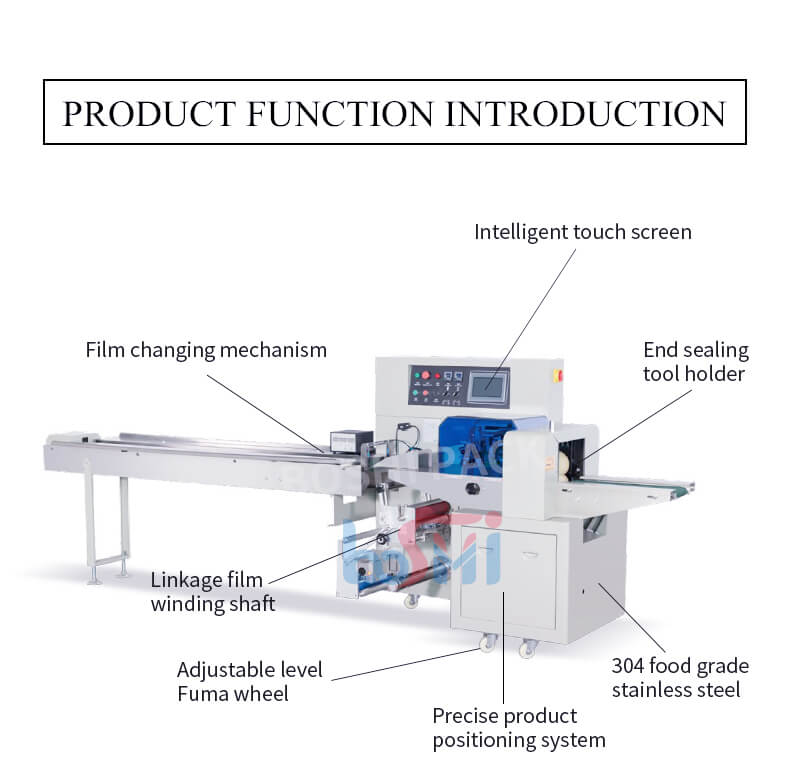

Product advantage:

* Food grade SUS#304 contact parts

* Color touch screen 7", esay to look

* Withsafety guards

* Accurate length cutting

* With technical patent

* Easy to operate and clean

* Cutting can be change for different material

* Can be modified to servo control

* Only need 1 person to operate the machine, reduce labor costs

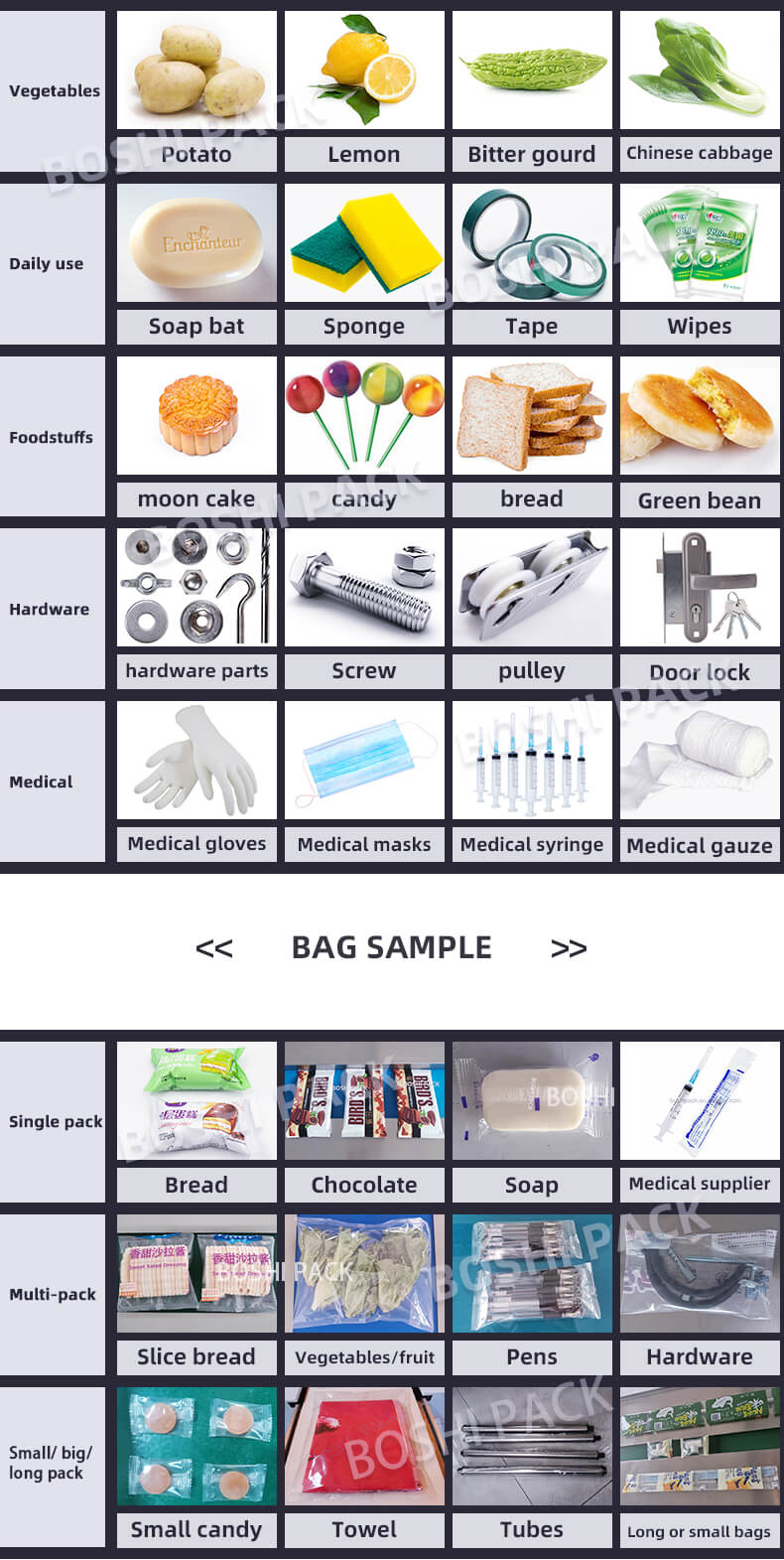

Product Applications:

suitable for bread packing, chocolate bar packing, sausage packing, popsicle packing, hardware packing, and etc.

Touch screen

Easy setting and cutting Save time and

film Multi-langues for your choice

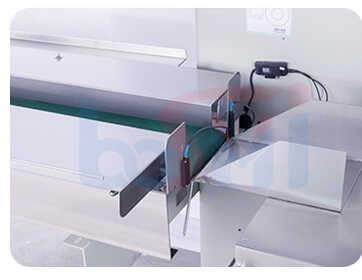

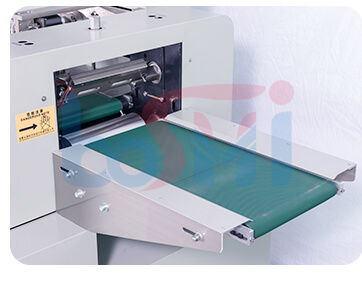

Feeding Conveyor

Sensor recognition put product on the belt casually

Through Beam Sensor

Auto identify product distance

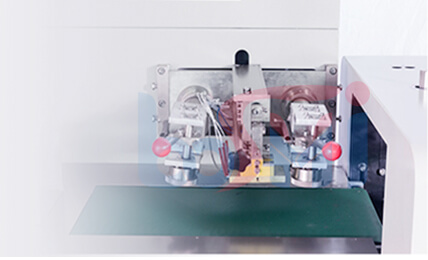

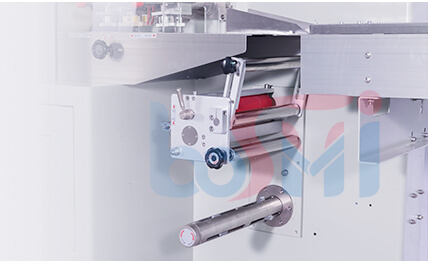

Mid-sealinf Parts

Independent PID temperature control Pull film Heater Lamination

End-sealing Cutter

Rotary cutter with fast packing speed Sealing bag end

Photoelectric Sensor

Tracking eye mark on the film Cut bag according eye mark

| Model | BS-350X |

| Film width | Max.350mm |

| Film thickness | 0.03-0.1mm |

| Bag width | 50-160 mm |

| Bag length | 65-190 mm, 90-220mm, or 150-330 mm |

| Product height | 40-60 mm |

| Packing speed | 40-180 bags/ min |

| Power | 2.6 KW |

| Machine dimensions | 4020*770*1450 mm |

| Machine weight | 680 kg |

| Option devices | Date printer, hole puncher, label machine |

| Packing film materials | OPP, CPP, OPP/PE, PET/ PE, Aluminum, and etc. |