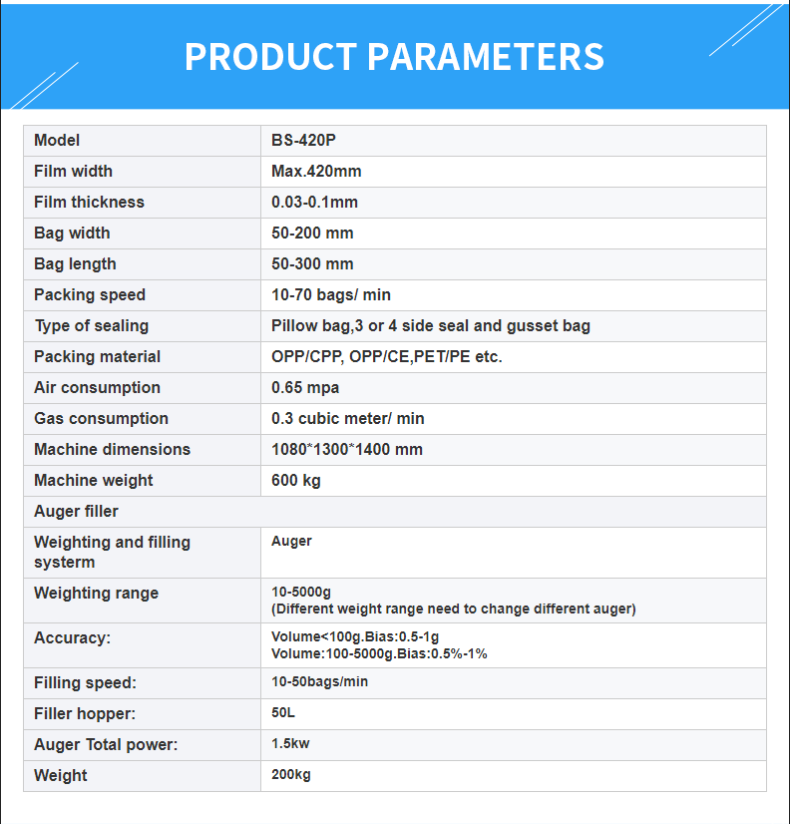

Fully automatic putty powder packing machine

1)The servo motor version, high speed output, stable operation, saving time and film.

2)Specific powder counting system controlled by servo motor.

3)Interface features easy and quick setting and operation.

4)High sensitivity photoelectric eye color tracing, numerical input of cutting sealing position for extra accuracy.

5)Temperature independent PID control, more suitable for packaging different materials.

6)Positioned stop function, without sticking knife or wasting film.

7)Simple driving system, reliable working, convenient maintenance.

8)All control is realized through software, easy for function adjusting and technical upgraded.

Fully automatic putty powder packing machine

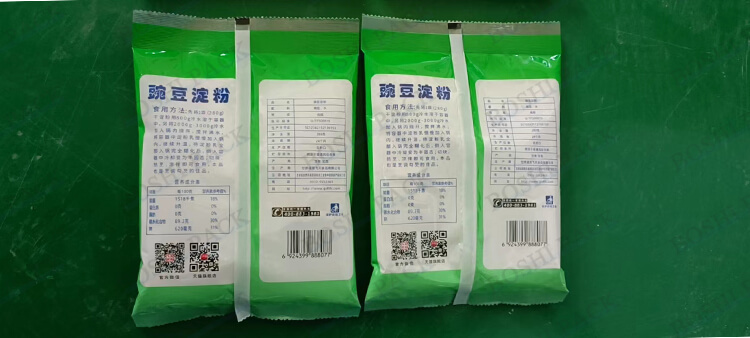

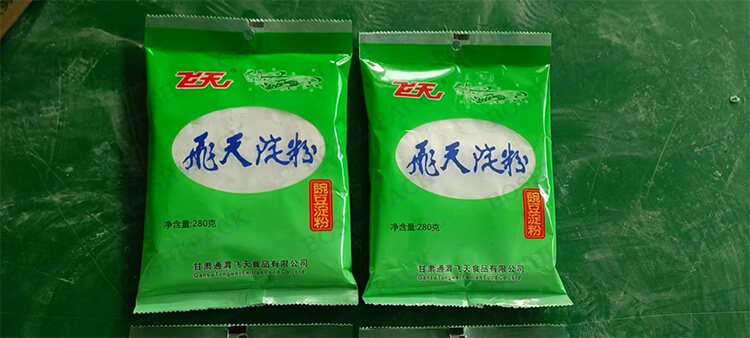

OUR ONE PACKING CASE FROM FAMAOUS COMPANY-------Customer use

2) Auger filler

3) Packing machine host

4) Finished products conveyor( If needed)

1)Simple structure in linear type ,easy in installation and maintain.

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3) High pressure double crank to control the die opening and closing.

4) Running in a high automation and intelligent ,no pollution

5) Apply a linker to connect with the air conveyor ,which can directly inline with filling machine .

Automatic weighing and stirring to realize mixing of various powdersPackaging, high precision, servo motor control, fast speed, High stability

Precise feeding, made of high-quality alloy steel, wear-resistant, corrosion-resistant,long lasting.

Sealed feeding, not easy to dust, servo motor control, speedfast and stable.

Using servo motor to control film pulling, fast speed and accurate size, high stability, automatic correction, suitable for a variety of different materialsroll film, such as non-woven fabric, film, composite film, aluminized filmetc

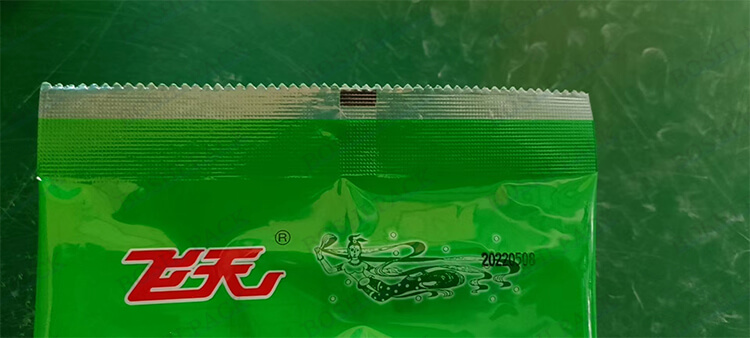

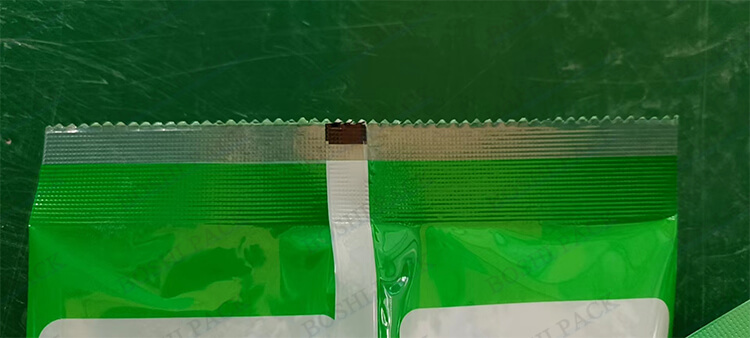

Different sealing and cutting can be selected according to the bag style incision and texturedevice.

The automatic powder filling machine is equipped with a screw auger filling dosing system that allows precise and effective packaging of powders instead of manual, helping to reduce labor costs and time. Automatic powder packing machine has large carrying capacity, good sealing with no dust, pollution and leakage.

<CERTIFICATION>