professional pillow packing machine manufacturers | Automatic ice lolly popsicle filling packing packaging machine

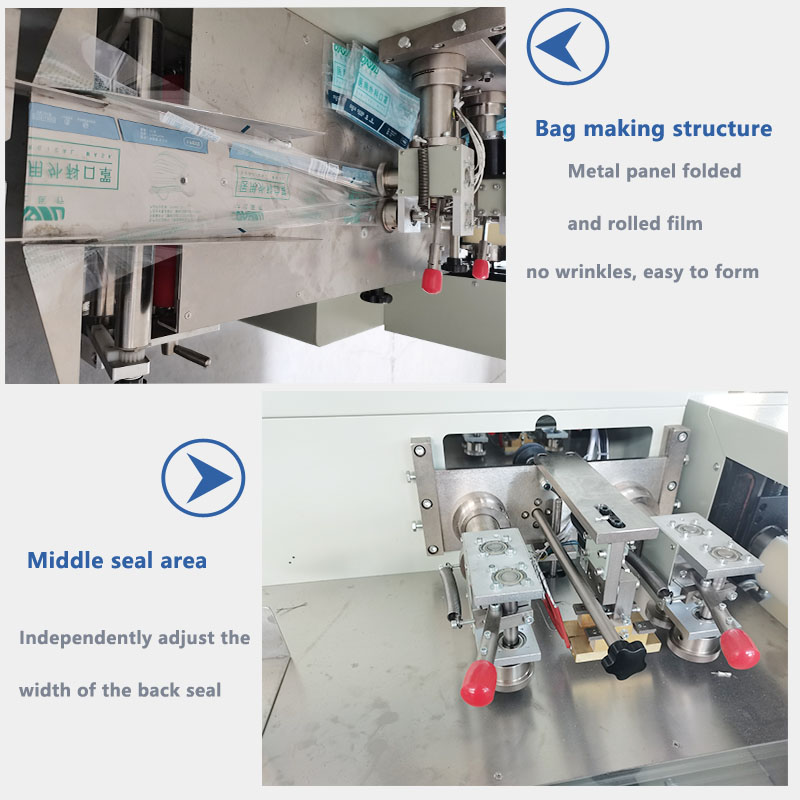

The advantage of three servo motor automatic flow packing machine

1)Three servo motor version, high speed output, stable operation, saving time and film.

2)Interface features easy and quick setting and operation.

3)Self failure diagnosis, clear failure display.

4)High sensitivity photoelectric eye color tracing, numerical input of cutting sealing position for extra accuracy.

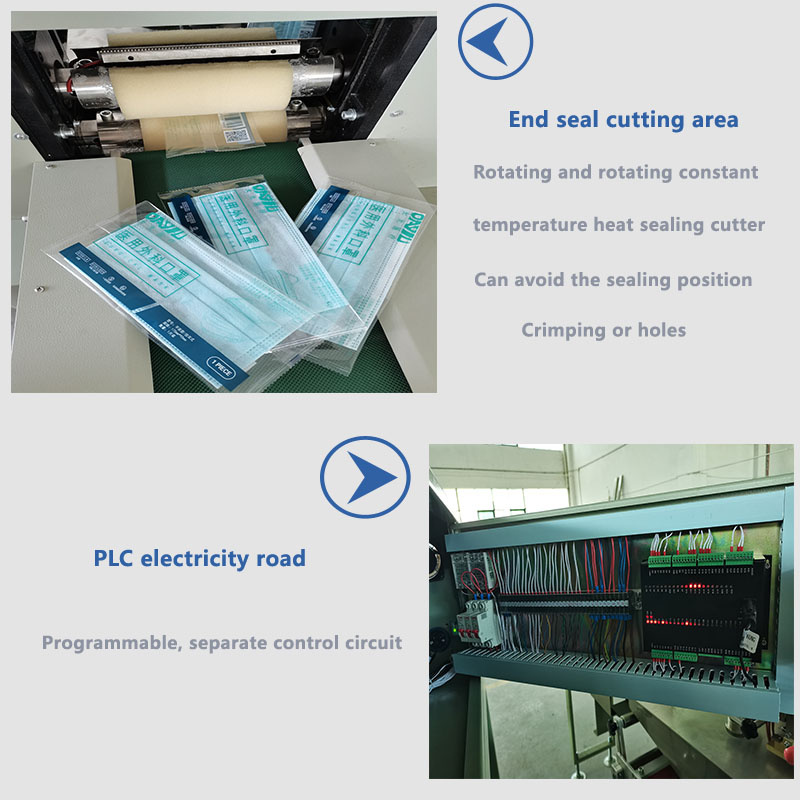

5)Temperature independent PID control, more suitable for packaging different materials.

6)Positioned stop function, without sticking knife or wasting film.

7)Simple driving system, reliable working, convenient maintenance.

8)All control is realized through software, easy for function adjusting and technical upgraded.

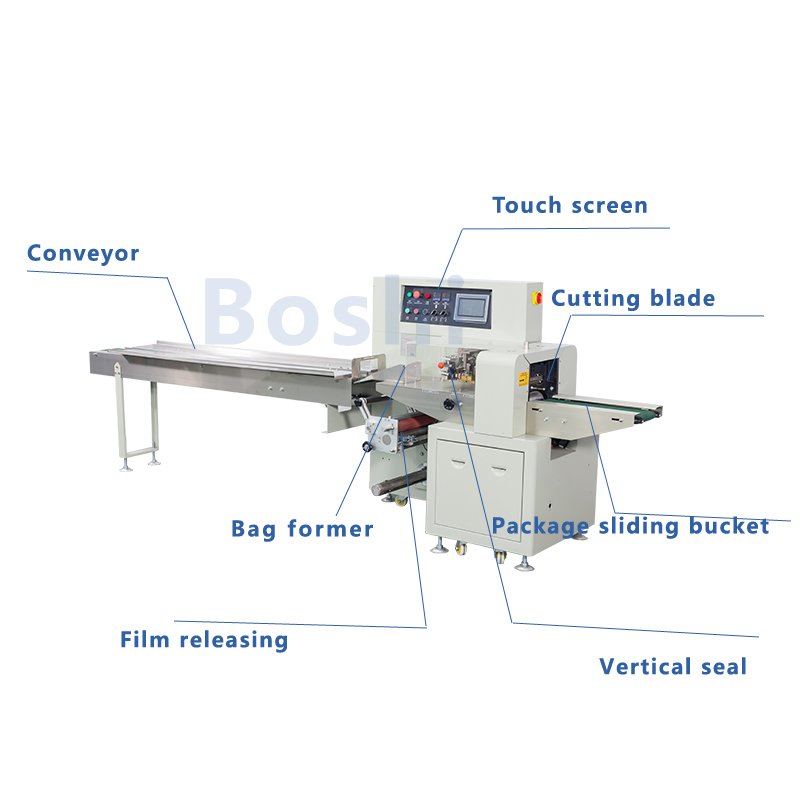

Automatic ice lolly popsicle filling packing packaging machine

(hardware pillow packing machine, suitable for packing screw, faucet, handle, and etc.)

professional pillow packing machine manufacturers

(such as laminated film, ((PET/ PE, OPP/CPP,OPP/ CE)), paper.

Option Device

CE, ISO, Google partner, Alibaba partner, and Chinese government certifications.

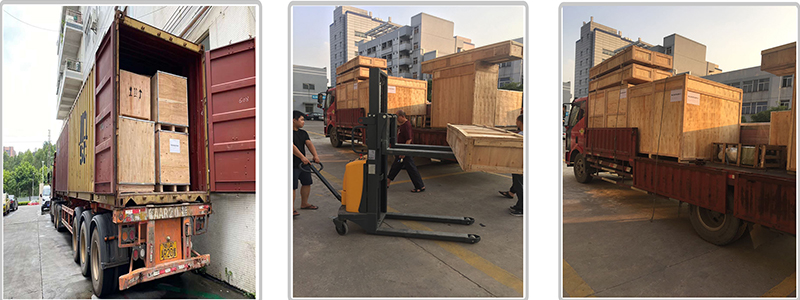

(Standard export wooden cases.)

(Standard export wooden cases.)

| Model | BS-250 |

| Film width | Max.250mm |

| Film thickness | 0.03-0.1mm |

| Bag width | 30-110 mm |

| Bag length | 65-190 mm, or 120-280mm |

| Product height | 55 mm |

| Packing speed | 40-230 bags/ min |

| Power | 2.4 KW |

| Machine dimensions | 3770*680*1420 mm |

| Machine weight | about 500 kg |

| Option devices | Date printer, hole puncher, label machine |

| Packing film materials | OPP, CPP, OPP/PE, PET/ PE, Aluminum, and etc. |