soap packing machine | Factory price automatic soap wrapping packing machine for packaging round soap

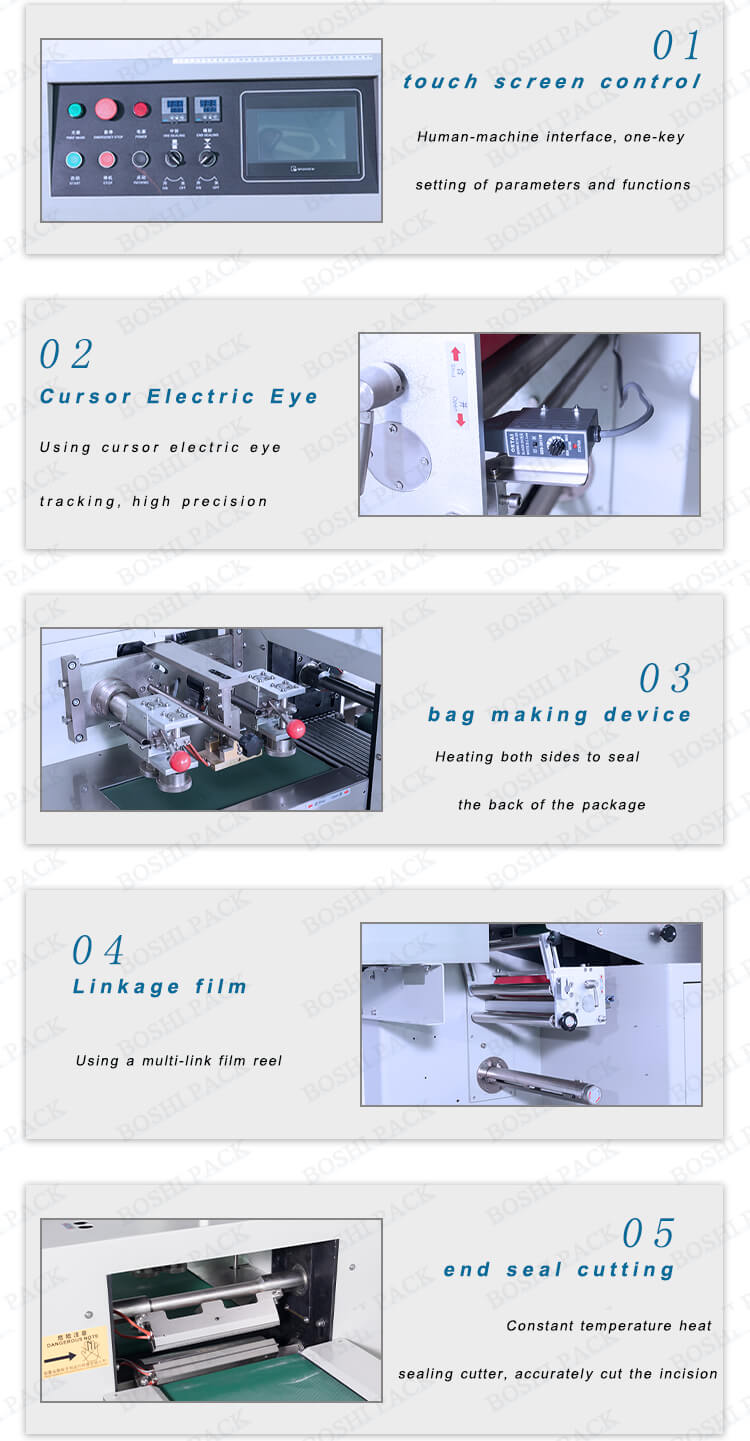

The advantage of three servo motor automatic horizontal packing machine

1)Three servo motor version, high speed output, stable operation, saving time and film.

2)Interface features easy and quick setting and operation.

3)Self failure diagnosis, clear failure display.

4)High sensitivity photoelectric eye color tracing, numerical input of cutting sealing position for extra accuracy.

5)Temperature independent PID control, more suitable for packaging different materials.

6)Positioned stop function, without sticking knife or wasting film.

7)Simple driving system, reliable working, convenient maintenance.

8)All control is realized through software, easy for function adjusting and technical upgraded.

Factory Price Automatic Soap Wrapping Packing Machine For Packaging Round Soap

soap packing machine

►Applicaton:

Flow pillow packing machine, suitable for packing daily use etc.

►Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Please tell us the following information while you send us an inquiry. Base on your message, we will suggest the optimum solution to you for reference. Thank you.

1. Your product

2. Bag dimension

3. Bag weight

4. Bag shape

►Product Advantages:

►Product Advantages:

1. Self-fault diagnosis is available for clear fault display.

2. The interface is easy and quick to set up and operate with high-precision structures.

3. The three servo motor version of the pillow packaging machine has high-speed output to ensure stable operation, saving time and film.

4. With PLC touch screen and fully automatic measuring, filling, bagging, date printing/nitrogen charge/string bags/easy tearing packing in one step, easy and accurate to set the bag length.

(such as laminated film, ((PET/ PE, OPP/CPP,OPP/ CE)), paper.

WHY CHOOSE BOSHI

(Standard export wooden cases.)

(Standard export wooden cases.)

| Model | BS-250 |

| Film width | Max.250mm |

| Film thickness | 0.03-0.1mm |

| Bag width | 30-110 mm |

| Bag length | 65-190 mm, or 120-280mm |

| Product height | 55 mm |

| Packing speed | 40-230 bags/ min |

| Power | 2.4 KW |

| Machine dimensions | 3770*680*1420 mm |

| Machine weight | about 500 kg |

| Option devices | Date printer, hole puncher, label machine |

| Packing film materials | OPP, CPP, OPP/PE, PET/ PE, Aluminum, and etc. |