sugar fondant extruding packing machine | Boshi pack China automatic fondant extruding packing machine manufacturer

Full automatic production line with 2 in 1 functions( extruding and packing functions)

Reduce manual operation and avoid touching products, no pollution and deformation

Easy operation and clean

High speed for cutting and packing

Accurate length cutting

Stable performance

With patent

Easy operation and clean

Use different cutting knife for different product

2 touch screens (extruder & packing machine) for convenient operation

Fit for different product length

Please note:

The bag size can be custom make so means that the weighting can be cutting in the machine.

Boshi pack China automatic fondant extruding packing machine manufacturer

The machine suitable to pack Modeling Clay, Play dough ,Plasticine ,Sugar paste,Candy mud ,Child mud, Super light clay,Crystal mud,.

Energy bar,Tamarind fruit, Fire mud,Slime,Self hardening sculpture modeling clay, Magnetic plasticine ,Terra-cotta plasticine clay and other sofe material product.

* Full automatic soft materials production line with extruding and packing functions,

* 2 touch screens (for extruder & packing machine)to make two machine can work

* Contact parts use food grade SUS304 stainless steel,save and clean.

* Reduce manual operation and avoid touching products, no pollution and deformation.

* Accurate length cutting, high gram precision.

* Machine with stable performance,easy operation.

* Independent PID temperature control, good for different packing film sealing.

* With auto alarm function,any alarm will show on touch screen.

sugar fondant extruding packing machine

Machine details:

Extruder hopper

This picture including extrude hopper+mixing screws+extrude

screws+extruder mold

Mixing screws

*Can stir all the soft materials to extrude tube.

*Use thickness sus304 With strong engulfing ability

Extruder mold

*Use food grade extruder mold

*Support to make square/round shape and pattern shape

*Easy to change different size extruder head

Sugar fondant /Play dough/clay /material cutter

Each material will be have it's own cutter.

Some material is sticky ,then will have teflon cutter.

We will according to your material to match suitable cutter to you.

Extruder hopper

Just need to put your items in this hopper, machine will auto

stir and extruder the shape you need.

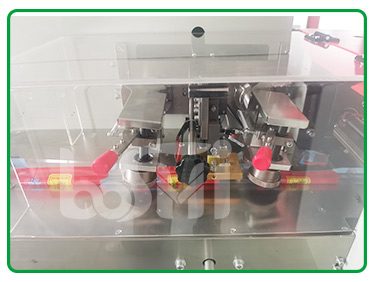

End Seal Cutter Area

*Constant temperature heat sealing cutter is used to seal the front and rear ends of packaging products.

*Angle inserting device is selected to make the bag beautiful and avoid curling at the sealing position.

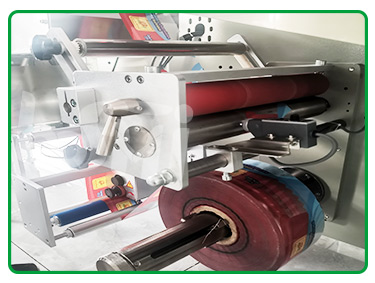

Mid- sealing structure

* With pulling film wheels+high quality copper +pressing wheels

*After this part , back bag sealing well.

Install Film structure

*Motor Control Film Structure

*High quality grinding rollers,Pull evenly,more beautiful packaging

*Film position can be easily adjusted by hand shank

1. What does your after-sales services?

Manual Installation Book, video support, on-line support. Also engineers overseas.

2. Are you factory or trading company?

We are the factory, we doing this line for more than 15 years.

3. What's your payment way?

T/T by our bank account directly, or by West Union, or in cash.

4. How can we make sure about the machine quality after we put the order?

Before delivery, we will send you the pictures and videos for you to check the quality,

and also you can arrange for quality checking by yourself or by your contacts in the third party inspection organization.

5. We are afraid you won't send us the machine after we send you the money?

Please note our above business license and certificate.

<Certification>

| Model | BS-350XL |

| Film width | Max.350mm |

| Film thickness | 0.03-0.1mm |

| Bag width | 50-160 mm |

| Bag length | 65-190 mm, 90-220mm, or 150-330 mm |

| Product height | 40-60 mm |

| Packing speed | 40-180 bags/ min |

| Power | 7 KW |

| Machine dimensions | 4020*770*1450 mm |

| Machine weight | 1100 kg |

| Option devices | Date printer, hole puncher, label machine |

| Packing film materials | OPP, CPP, OPP/PE, PET/ PE, Aluminum, and etc. |